1. What is modular hydraulic trailer?

2. Advantages of Shiyun modular trailer

3. Applications of hydraulic modular trailer

4. Main components of a modular trailer

A modular trailer accounts for various special trailers or semi-trailers that are normally used to transport large cargos that are difficult to disassemble.

These types of vehicles are basically used for the transportation of heavyweight and bulky objects. Modular trailers are commonly used in the chemical industry, power stations, construction industry and in the iron and steel industry. Due to their excellent lateral stability, they can be used for mining operations. They are also used to transport products that are over-length. The tractor trucks are used to provide traction for the modular trailers.

Shiyun modular trailers come in different modular units that include 2, 3, 4, 5, 6, and 8 axle models. The maximum load per axle is up to 40 tons. A larger number of axle lines means that the modular trailer has a higher loading capacity.

1. Quality tests:

Tests are usually done on loading, offloading, heavy loading and overloading on different grounds. The durability and use of modular trailers on sloppy grounds are also ascertained. This is carried out to mature the performance of the trailers and make them applicable in different parts of the world.

2. Performance characteristics:

The performance of a modular trailer is very vital to clients and therefore, the steering and control features are an important aspect in the construction. The source of driving power and the hydraulic systems installed put together ensure faster travelling speeds in the movement of cargo. Modular trailers with faster responses in steering and lifting operations. They are well-synchronized and equipped with a faster ratio reducer to provide a bigger driving force.

3. Hydraulic technology:

This is a very special feature that distinguishes most modular trailers. Through it, they have become a unique innovation and useful equipment in the loading and transportation of heavy weight cargo. The desire to address real engineering needs in the transportation industry prompted the push for new and less-sophisticated systems that are economically feasible. This technology has enabled precise positioning, loading and movement of cargo.

4. Steering capabilities:

High-axle loading demands stable steering operations. Shiyun modular trailers have advanced in this aspect and have continued to provide equipment with high steering resistant moment. Additionally, they offer axial force containment abilities and can safely handle the overturning moment, the torque and the radial force or any other intricate joint effect. It is a development that has also matured the modular trailers’ design hence boosting the reliability and confidence during operations.

5. Load-bearing abilities:

The need for high-end modular trailers to transport heavy weight cargo is ever on the increase around the globe. As a result, Shiyun modular trailers have continued their developments in this area by providing a robust frame that can withstand high loading operations. Ideally, the frame is the most important trailer feature because it is meant to take this weight during loading, transportation and offloading operations.

Quality in the construction of the frame structure has been enhanced through automated Computer Numerical Control (CNC) milling procedures. These are more advanced technologies than the conventional integrated structure that has been use over many years. Any issues of deformation are well-taken care of.

1. Heavy equipment transport:

Every company that uses heavy equipment in its production process requires a special vehicle to move the equipment from the manufacturer to its warehouse.

Some companies deal in buying and selling heavy equipment. SPMTs offer great solutions to such companies. The heavy cargo in this case ranges from machinery and equipment to stacks of finished products or raw materials. The modular transporters can be customized to transport any cargo as long as it is well packaged.

Heavy equipment manufacturers require transport solutions to transport components to their assembly units. Some of the parts include long and wide metallic beams depending on the final products.

The modular multi axle trailers provide a reliable solution for all companies that use heavy and bulky equipment in their production processes.

2. Project construction:

Modular trailers are commonly used to transport construction blocks include concrete blocks to construction sites. Concrete bridge and road sections are safely transported using these heavy transporters.

The modular multi axle trailers are also used to ferry construction materials in bulk such as cement, ballast, and sand among others.

Applications of hydraulic modular trailer

3. Shipbuilding industry:

Ships are assembled in shipyards before they are transported to the shore. In most cases, the shipyards are located miles away from the sea shores.

Moduler trailers are used to transport sections of a ship or the whole from the shipyard to their designated place. Ships are part of the heaviest loads that are transported on the road.

The modular multi axle trailers have enough capacity and space to accommodate such heavy and bulky cargo.

4. Electric power construction:

The companies involved in constructing power plants use heavy machinery and equipment to set the plants. Large power plants use the heaviest parts because of the capacity required.

The companies rely on modular trailers to move their construction equipment and heavy component to the power plants. Power plants are mostly made of large and heavy steel beams.

5. Oceanographic engineering:

Oceanographic instruments, equipment, and devices are also assembled off-site and then transported to the sea using hydraulics modular trailers. The ocean environment does not support the manufacturer and repair of equipment.

The functions must be done in an assembly unit on land before the equipment can be moved to the right destination. The modular multi axle trailer provide a convenient way for the manufacturers to move the equipment to the seashore.

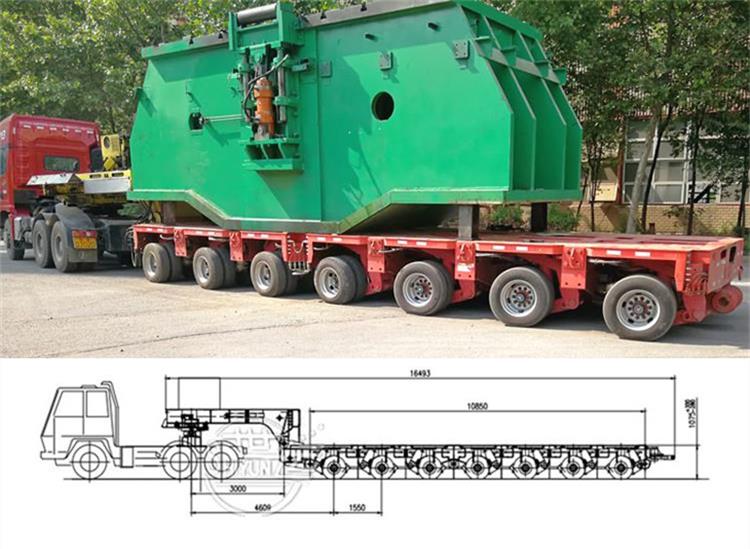

Shiyun modular multi axle trailer loading tests

1. Frame

The main girder of frame has a box-type carrying beam structure. The girder uses high-performance welding steel to ensure stability and reliability.

The surface of the main structure should be treated with sand blasting. The thickness of the painting used on the surface should meet the national standards. The brand of the painting used should be among the top brands in the world. All the small-sized parts of the frame should be zinc-plated.

The box-shaped center beam and the stable crossbeams give the frame a high degree of rigidity. Hence, the frame can achieve its optimal loading level. The steering system, air tank, and hydraulic oil tank are all integrated into the bogie frame. Thus, the parts are protected against damage and corrosion.

The frame has a reinforced loading deck, which allows extreme point loads. The optimized bolt-plate coupling, on the other hand, eliminates any problems that may arise when assembling the longitudinal combinations.

2. Hydraulic Wheel Bogie

The modular hydraulic trailer uses a hydraulic wheel bogie, which consists of the bogie frame, hydraulic cylinder, axle, tyre, and rocker arm. It has a strong load capacity.

When the road is uneven on the transverse direction, the axle swings to compensate. If the road is uneven in the driving direction, the hydraulic lifting system adjusts the modular supporting system. The modular unit can assume 3-point or 4-point supporting system to ensure that each supporting point carries an even load.

3. The Mechanism of Steering

The steering mechanism consists of the steering central panel, steering orifice plate, steering cylinders, and steering rods.

The steering orifice plate is welded together with the bogie frame. The plate has specific quantities of assembling holes that are used to install steering rods. The positions where steering rods are installed on the steering orifice plate can be changed to suit different combination modes of the modular unit.

The modular hydraulic trailer uses three major steering modes that include the all wheel steering along (over five axle lines), diagonal steering along, and the front-wheel steering mode. The steering rods can be adjusted quickly and easily to suit the desired steering angle.The modular has a hydro-mechanical all-wheel system with a two-circuit system, which ensures that the steering system maintains its functionality even when one or more steering circuit fails.

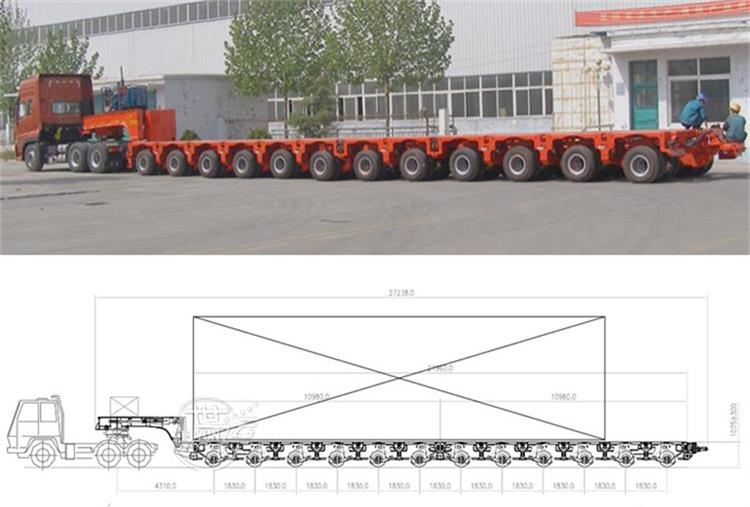

10 axles hydraulic modular trailer details display

4. Hydraulic System

The pump in a hydraulic modular trailer uses the hydraulic technique, which is effective in controlling the driving speed.The steering and suspension pumps use the constant pressure controller to realize a quick response whenever they need steering power.

The driving motor switches between driving and follows uses a large torque radial motor. All the hydraulic cylinders in the transporter have anti-block valves, which are important when the pipe line is broken.

5. Lifting System

The total lifting length of modular unit’s platform is 600mm. The platform gives a compensation of ±300mm, which is enough compensation for the axial load.

The suspension cylinder is installed as the steer wheel bogie. The two ends of the suspensions have joint bearings, which protect the cylinder from damages.

The hydraulic accumulator provides good cushioning when the modular transporter is unloaded.

6. Hydraulic Suspension

The individual swing axles in a hydraulic modular trailer consist of the hydraulic suspension, which can be connected to different support circuits.

The purpose of connecting the suspension to different circuits is to ensure that the axles have equal loads. When the axles have equal loads, you are guaranteed of the optimal lengthwise and crosswise leveling even if you are driving on uneven terrain. The equal loads also regulate extreme cross falls.

7. Combination System

All modular units can be combined side-by-side or from end-by-end. A hydraulic link-pin is used to combine modular units end-by-end.

Combining hydraulic and brake pipeline requires fast coupling connectors, which have a high performance level. The electric interfaces use a heavy connector, which is reliable.

8. Brake System

The modular unit is equipped with a compressed air brake system. The system consists of double brake chambers, single brake chambers, relay valves, brake drums, and reservoirs.

The brake system consists of tow brake lines that function as the service brake and the parking brake.